Plastic Blind Drain - Good Compressive Strength and Flexibility

Plastic blind drain is also called blind ditch or under drain. It is made of plastic core and outer filtering cloth. Plastic core body is a thermoplastic synthetic resin as the main raw material, after modification, in the melt state, through the nozzle pressed thin plastic wire strip, by forming device for extruded plastic wire in contact welding to form three-dimensional network structure. What's more, it has many shapes, including rectangular shape with many holes, rectangular shape with empty center, rectangular shape with double empty centers, round shape with many holes, round shape with empty center and many other structural forms.

The plastic blind drain overcomes the disadvantages of the traditional blind ditch. With some advantages of good drainage, excellent pressure resistance, lightweight, good flexibility, greatly reduce the labor intensity of workers, and construction efficiency. Therefore it has been widely welcomed by the most engineering projects, such as, highway and roadway subgrade, retaining wall, landfill, roof garden, building foundation, underground irrigation and so on.

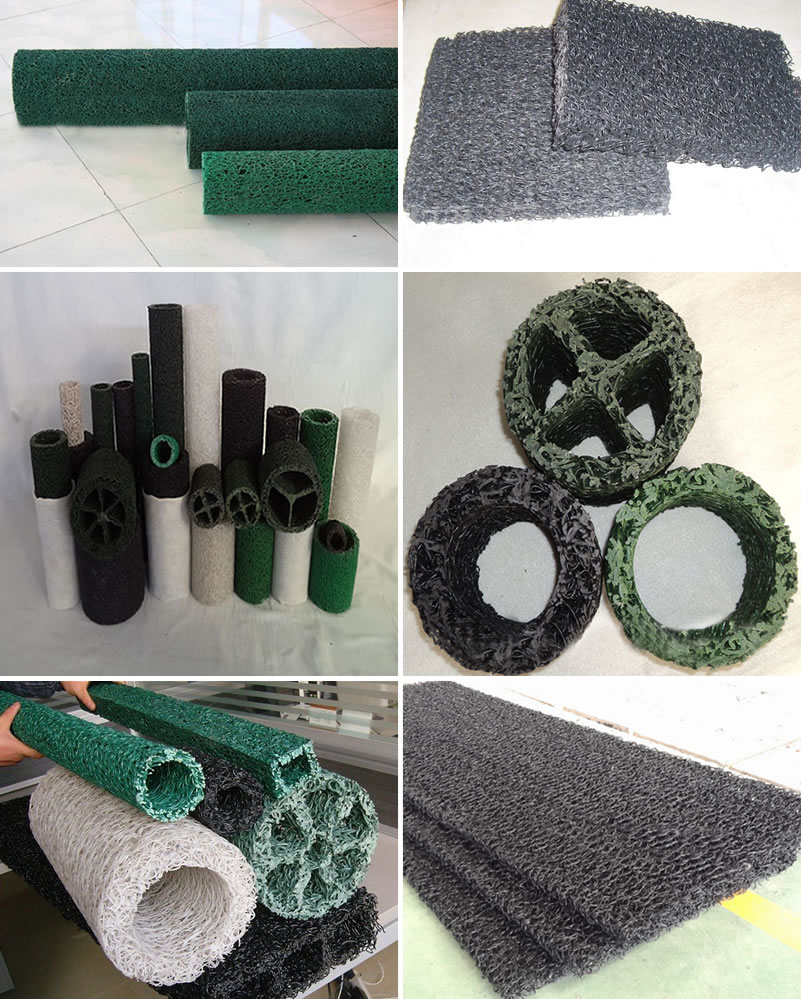

PBD-1: Circular plastic blind drain.

PBD-2: Rectangular plastic blind drain.

Specifications:

- Product name: plastic blind drain.

- Material: thermoplastic synthetic resin.

- Color: green, black and white. Other colors are also available according to your requirements.

- Shape: square, circular, sheet.

- Diameter: 50 mm - 400 mm.

- Length: 2 m - 50 m.

- Note: the length of plastic blind drain can be customized.

| Item | Spec and property | Rectangular plastic blind drain specification | |||

|---|---|---|---|---|---|

| MF7035 | MF1235 | MF1550 | |||

| 1 | Exterior size (w × h) (mm) | 70 × 35 | 120 × 35 | 150 × 50 | |

| 2 | Hollow size (w × h) (mm) | 40 × 10 | 40 × 10 × 2 | 50 × 25 × 2 | |

| 3 | Mass per unit length (g/m) | 367 | 600 | 992 | |

| 4 | Porosity (%) | 82 | 88 | 87 | |

| 5 | Compressive strength (KPa) | compression rate 5% | 98 | 73 | 46 |

| compression rate 10% | 171 | 106 | 75 | ||

| compression rate 15% | 174 | 142 | 118 | ||

| compression rate 20% | 229 | 170 | 151 | ||

| 6 | Discharge capacity (m/h) | Calculating formula | 0.5737 Q=15.84H L=0.5 | 0.6042 Q=6.12H L=0.5 | 0.888 Q=10.98H L=0.4 |

| hydraulic slope i-0.1 | 1.001 | 2.84 | 0.629 | ||

| hydraulic slope i-0.05 | 0.659 | 1.913 | 0.415 | ||

| hydraulic slope i-0.01 | 0.249 | 0.761 | 0.099 | ||

| hydraulic slope i-0.005 | 0.164 | 0.551 | 0.054 | ||

| hydraulic slope i-0.001 | 0.062 | 0.1203 | 0.013 | ||

| Item | Spec and property | Circular plastic blind drain specification | ||||||

|---|---|---|---|---|---|---|---|---|

| MY60 | MY80 | MY100 | MY120 | MY150 | MY200 | |||

| 1 | Exterior size (w × h) (mm) | ф60 | Ф80 | Ф100 | Ф120 | Ф150 | Ф200 | |

| 2 | Hollow size (w × h) (mm) | Ф25 | Ф45 | Ф55 | Ф75 | Ф80 | Ф130 | |

| 3 | Mass per unit length (g/m) | 452 | 813 | 1145 | 1520 | 1520 | 3010 | |

| 4 | Porosity (%) | 82 | 82 | 85 | 85 | 88 | 89 | |

| 5 | Compressive strength (KPa) | compression rate 5% | 82 | 77 | 67 | 52 | 47 | 47 |

| compression rate 10% | 162 | 142 | 112 | 80 | 72 | 70 | ||

| compression rate 15% | 202 | 182 | 162 | 102 | 92 | 90 | ||

| compression rate 20% | 252 | 232 | 222 | 127 | 122 | 112 | ||

| 6 | Discharge capacity (m/h) | Calculating formula | 0.5371 Q=6.12H L=0.5 | 0.531 Q=19.8H L=0.5 | 0.5303 Q=19.44H L=0.5 | 0.5333 Q=31.32H L=0.5 | 0.4686 Q=56.88H L=0.5 | 0.4726 Q=86.4H L=0.5 |

| hydraulic slope i-0.1 | 1.224 | 4.03 | 4.0 | 4.338 | 13.945 | 17.92 | ||

| hydraulic slope i-0.05 | 0.844 | 2.792 | 2.749 | 4.380 | 10.098 | 12.453 | ||

| hydraulic slope i-0.01 | 0.356 | 1.188 | 1.174 | 1.856 | 4.750 | 5.349 | ||

| hydraulic slope i-0.005 | 0.245 | 0.822 | 0.811 | 1.283 | 3.433 | 3.717 | ||

| hydraulic slope i-0.001 | 0.103 | 0.349 | 0.345 | 0.543 | 1.615 | 1.596 | ||

PBD-3: Plastic blind ditch in various structural forms, colors, shapes and sizes.

PBD-4: Details about plastic blind drain.

Features:

- Plastic blind ditch material composition fiber is about 2 mm silk, mutual contact point and melting into forming, and form into three-dimensional reticular body. Its principle is the same with the truss of steel structure principle. The surface opening rate is 95% - 97%, which is 5 times more than that of the porous pipe, is 3-4 times of the resin mesh tube. And its surface water absorption rate is extremely high.

- Due to the three-dimensional structure, its gap rate is 80% - 95%, constitute space is lightweight, compressive property is 10 times stronger above than resin for pipe structure. Therefore, even because of overload pressure, due to the three-dimensional structure, the residual porosity can reach more than 50%, does not exist the problem of water barrier, and no need to consider that it will be damaged by soil pressure.

- Great compressive strength, under 250 kPa pressure, the compression rate is lower than 10%.

- Add anti aging agent, durable, it can be placed in the water or the soil for a few decades, it can still ensure stability.

- Compression resistance and flexible, for the corners or other curves can also be construction, very light, if the depth of the backfill is in 10 cm or so, it can also be used for bulldozer backfill, etc.

- Because of the above characteristics, so traditional blind ditch on various issues, such as uneven settlement or due to overloading caused partial occlusion, crushed to interrupt function caused by void nothing, all can be resolved through the plastic blind drain materials.

- Due to the use of hot melt method to molding but not use binder, so it will not collapse by aging and peeling adhesive.

- Besides these advantages, plastic blind ditch also features permanent using life, easy for construction, good durability, lightweight, excellent flexibility, adapting to the deformation of soil, greatly decrease the labor intensity of workers and high construction efficiency.

Applications:

- Drainage for building roof garden.

- Ash heap drainage in thermal power plant.

- Drainage for tunnel and underground channel.

- As the drainage liner for pressure relief method.

- As the sieve material for sewage treatment projects.

- Drainage for retaining wall (vertically and horizontally).

- Drainage for treatment of soft soil foundation horizontally.

- Drainage for roadbed and road shoulder of highway, railway.

- Drainage for hillside slopes, bank slopes and embankment slopes.

- Drainage for subways, underpasses and underground freight yards.

- Drainage for coal piling field, wastes landfill sites, and fertilizer piling field.

- Underground irrigation and drainage systems of agriculture and horticulture industry.

- Drainage for green field of sport field, golf course, baseball field, football field, airport, park and other green lands.

Packaging:

PP woven, black plastic film or double layers geotextile for outer packing, or at your request.

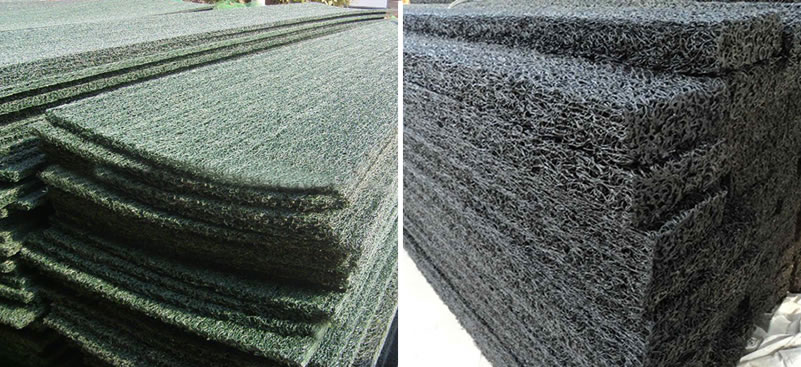

PBD-5: Circular plastic blind drains are waiting for package.

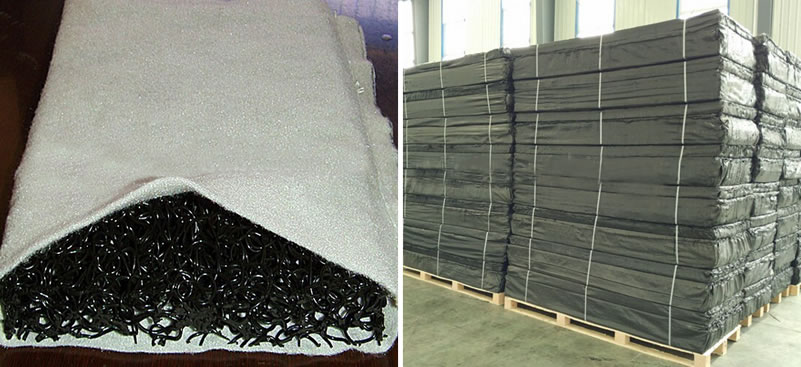

PBD-6: Circular plastic blind drain can be packaged with double layers geotextile.

PBD-7: Packaged circular plastic blind drains are waiting for transport, and large diameters sheathes small diameters can save space and freight.

PBD-8: Rectangular plastic blind ditches are prepared to pack.

PBD-9: The outside package of rectangular plastic blind drain can also be black plastic film.

Inquiry for Our Product

Hebei Wennian Trading Co., Ltd

E-mail:

Info@walcoom.com

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.